After some back and forth I decided to build some alternative midbass horns to my 150Hz Tractrix to experiment with. The initial idea was to build some horns which have a lower cut off frequency.

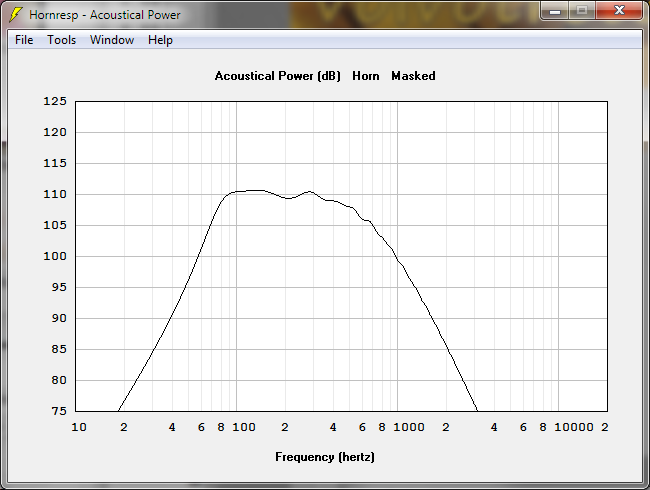

Considering the space we’ve got within our living room, I decided that the horn shall not exceed 1m in depth (including the back chamber) which lead me to a flare frequency of 77Hz. A pair of Electro Voice EVM15L I bought some time ago were planned to be the driver for these horns. Since the EV does not have the ‘highest’ mass roll off, only a unfolded horn was a possibility. To reduce the amount of mouth reflections I choose a mouth width/height ratio of 1:1.6. The throat was chosen to be square. The size of the throat is based on Keeles calculations as explained in Bruce Edgar’s Show Horn article (refer to download section). Initially I wanted to apply a hyperbolic exponential flare with a m-factor of 0.6. I simulated the predicted response of this horn and of several approximations (including a conical version). All these variants had the same throat and mouth dimensions as well as the same length. They differed only in the shape of the flare (bend vs. 2-step approximation vs. conical). The results of the simulation were very close to each other. A discussion on this topic on AA confirmed be that the conical approximation of the horn shall not be a bad choice (see discussion and simulations here).

In this place I have to admit, that all this would not be possible without the work and the help of Dr. Bruce Edgar and other inmates of High Efficiency Speaker Asylum forum. Thanks a lot to you guys!

Simulation

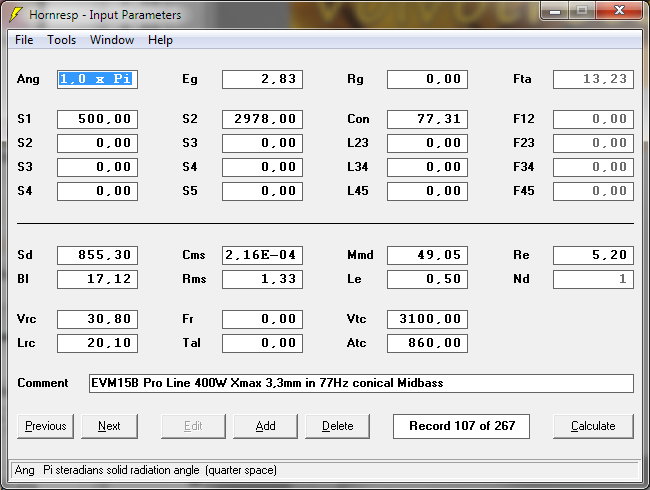

The simulation is based on the EVM15B which replaced the initial EVM15L.

Design Basis Summary

- total horn length (incl. back chamber) shall not exceed 1,00m

- the horn shall have conical approximation of a hyperbolic flare contur with m=0.6

- the horn shall have a 5/16 mouth size of a free space horn

- the horn shall have a 1:1.6 mouth ratio to minimize mouth reflections

- the horn shall not be folded to reach 500Hz upper xover frequency

- the horn shall use an EV EVM15L

Building the Horns

First I cut the boards very rough from sheet of 40mm MDF with a circular saw. Than I prepared two templates for pattern sawing to cut the pieces very precisely. The pattern is the thinner board on top which was simply nailed on the board to cut.

With the pattern, cutting is very easy and quick (This guy in the dust is me).

Here You can see how pattern sawing works out. The saw blade only cuts the thick MDF board. The template will just be touched by the blade. The saw fence is adjusted in such way that its left edge is aligned with the left edge of the saw blade.

This is shed where I do the cutting and turning.

A first look.

I was happy to see how good the pieces of the flare fit together.

Our daughter had a lot of fun crawling into the mouth and exiting throuth the back chamber.

View into the backchamber with speaker gasket.

Speaker installed. The volume will be adjusted later on, so that the first impedance peak will be at 77Hz. May be the amount of foam rubber stuff need to be adjusted.

Size comparison to the tractrix fronthorns.

Entire system just set up.