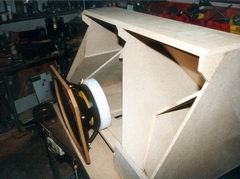

Pictures taken during construction

I just scanned the pictures I took back in ’95, when I built a single Klipsch bass horn to be used as a sub. This horn is based on an AutoCAD 3D model. The plans you’ll find in the download section. Maybe these pics help to answer question on where some of the small parts in the plans belong to. I also want to thank my friend Robert who helped me a lot building these horns.

And this is the driver I currently use (obsolete Eminence type):

Note

If I would build an other one of these, I’d use thicker wood for the internal parts (like 22mm). If you touch the inner parts when it plays loud, you can feel (very small) vibrations. I would not say that this is a problem, but an absolutely dead backchamber would put my mind at rest.

A more important thing is the choice of the bass driver: Although I did not try, I would start with the original Klipsch K33E bass driver. The reason is, that the Klipsch basshorn is a compromise speaker system: The horn is foreshortened i.e. it’s too short for the flare frequency and it’s mouth is too small as well. Down at it’s cut off frequency it more acts like a closed enclosure than a horn. PWK has most likely tested a large number of different drivers in this corner horn. I think that he specified a driver at the end, which conceals the weaknesses of the horn as good as possible. With most drivers suitable for horn loading, the Klipschorn lacks deep bass. Thus you’ll probably obtain best results with the K33E. And it’s not even that expensive as you might think. It’s like 120 Euro (approx. US$ 135).

These seem to be the specs of the original K33E (found somewhere on the www)

- Znom = 4 ohms

- Re(vc) = 3.5 ohms

- L = 1 mH @ 1kHz

- R = 1.03 ohm @ 1KHz

- Fs = 27Hz

- Sd = 890 cm² (13.5″ diameter)

- Xmax = 6.67 mm

- Vas = 343 liters

- Qts = 0.633

- Qes = 0.684

- Qms = 8.5

- BL = 9.8 T*m

- Mms = 106 grams

- Cms = 0.305 mm/Newton

- Pmax = 150 Watts

This recomendation for a suitable driver is from the www as well

- very low Fs (<25Hz)

- high Qts (>0.5)

- large Xmax (>6mm)

- large BL products >10 T*m

- Nominal impedence at 4ohms (horn loading brings it closer to 8 in operation)

- Compliance numbers around 0.3mm/N. The “orginal” plans call out a driver with lowest possible Fs preferably below 25Hz.